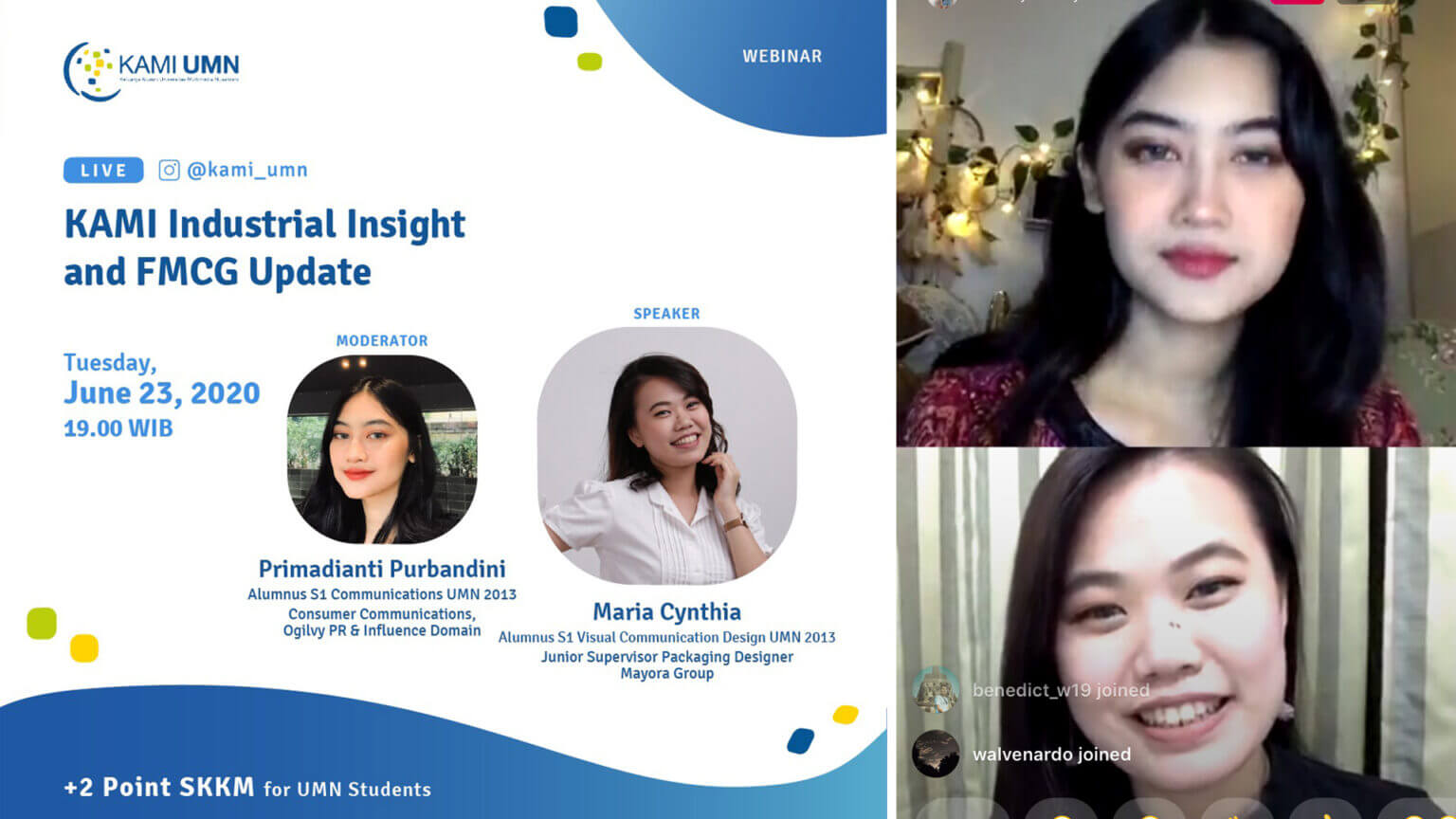

US UMN: WE Industrial Insight and FMCG Update

November 3, 2020

UMN Webinar: A New Era for Industry with Robotic Process Automation

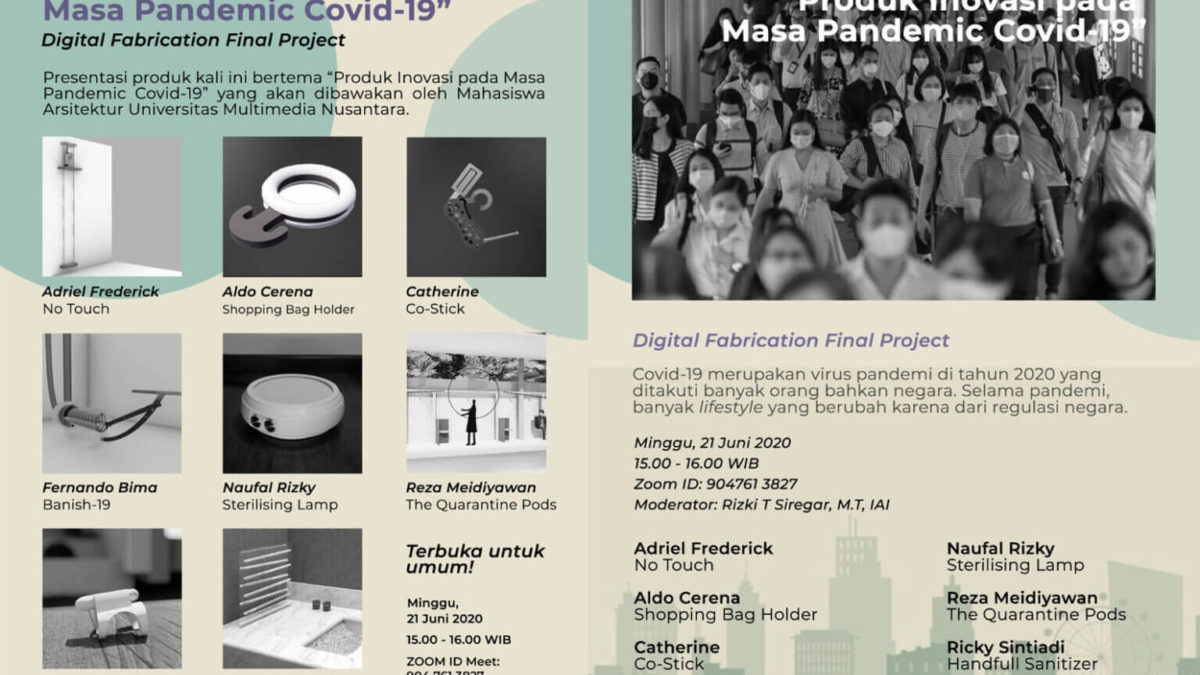

November 3, 2020TANGERANG – Students of the UMN Architecture Study Program design product designs as a solution to the COVID-19 pandemic in the 2019-2020 Even Semester Final Examination (UAS) for the Digital Fabrication course. Not only design, Lecturer in the Digital Fabrication course, Rizki Tridamayanti Siregar, explained that there are final results in the form of prototypes (initial products) for small-scale designs or mock-ups (three-dimensional miniatures) for large-scale designs.

“We do not focus on the problem, but focus on the solution. This task is not limited to what to make, it’s up to the students. Whether it is a small product, an architectural product, or an interior, “said Rizki in an online forum entitled” Innovation Products during the COVID-19 Pandemic “, Sunday (21/6).

At first the UAS Digital Fabrication theme was not the issue of COVID-19, but the COVID-19 pandemic gave rise to new ideas to answer people’s problems facing COVID-19 in everyday life. Rizki said that the idea came up. Through this innovative work, he hoped that the community could also develop other ideas.

“Previously, (we) planned to build an installation or pavilion to be built in a public place. However, because there is a pandemic, we have to divert the task a little (for the final Digital Fabrication project), “explained Rizki.

In Rizki’s presentation, the duration of this final project is around 2-3 weeks. For product processing techniques, he explained that they still use a combination of manual (hand-crafting) and digital (machine) methods.

The digital methods used, for example, 3D printing – a three-dimensional object printing machine – and lasser cutting – a laser cutting machine.